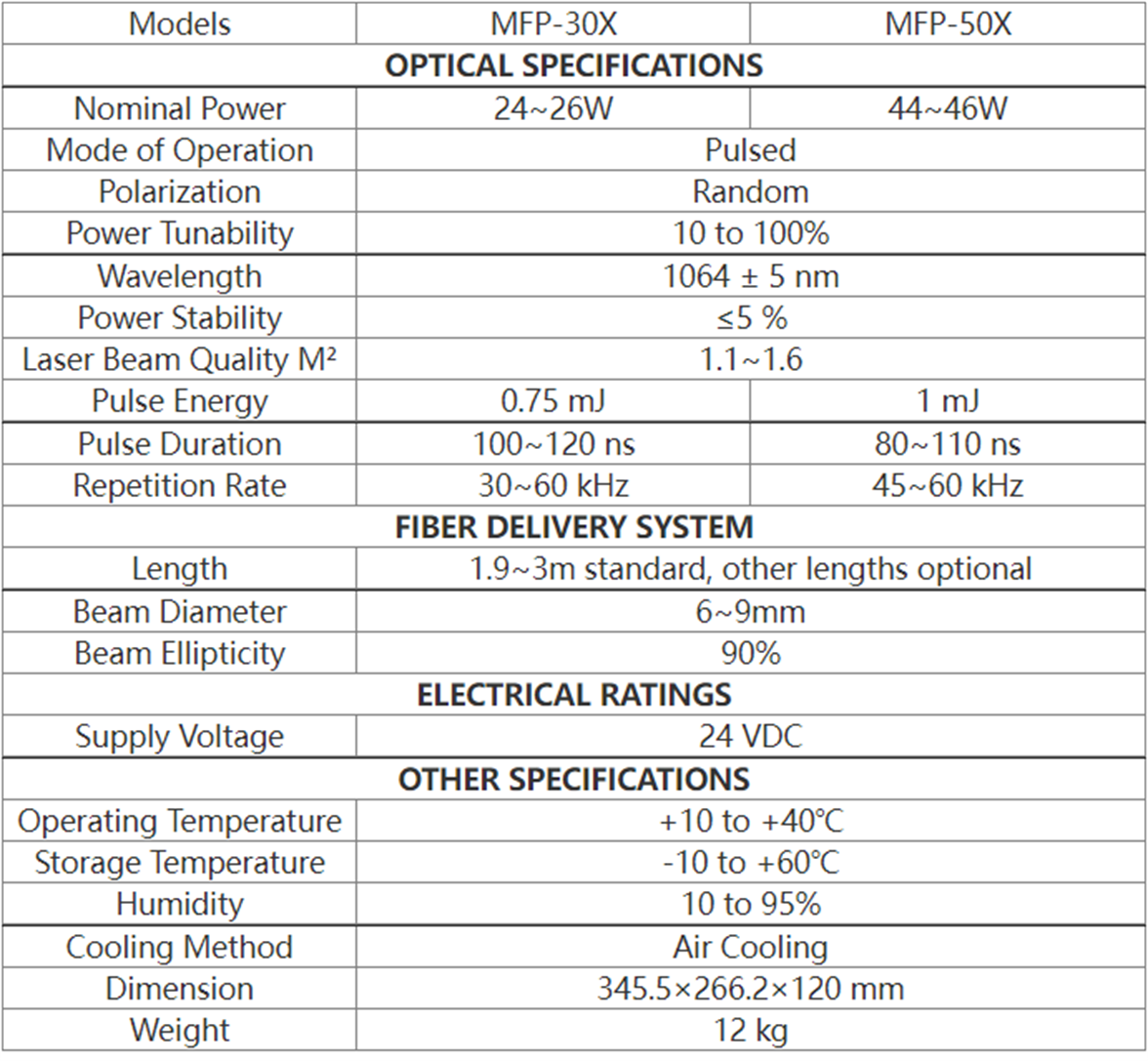

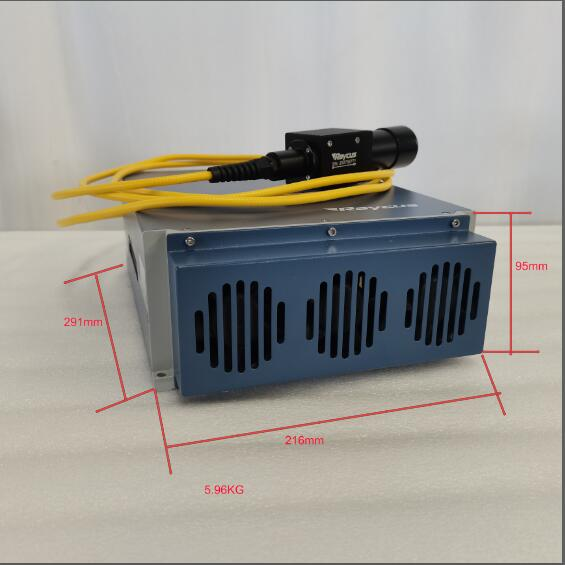

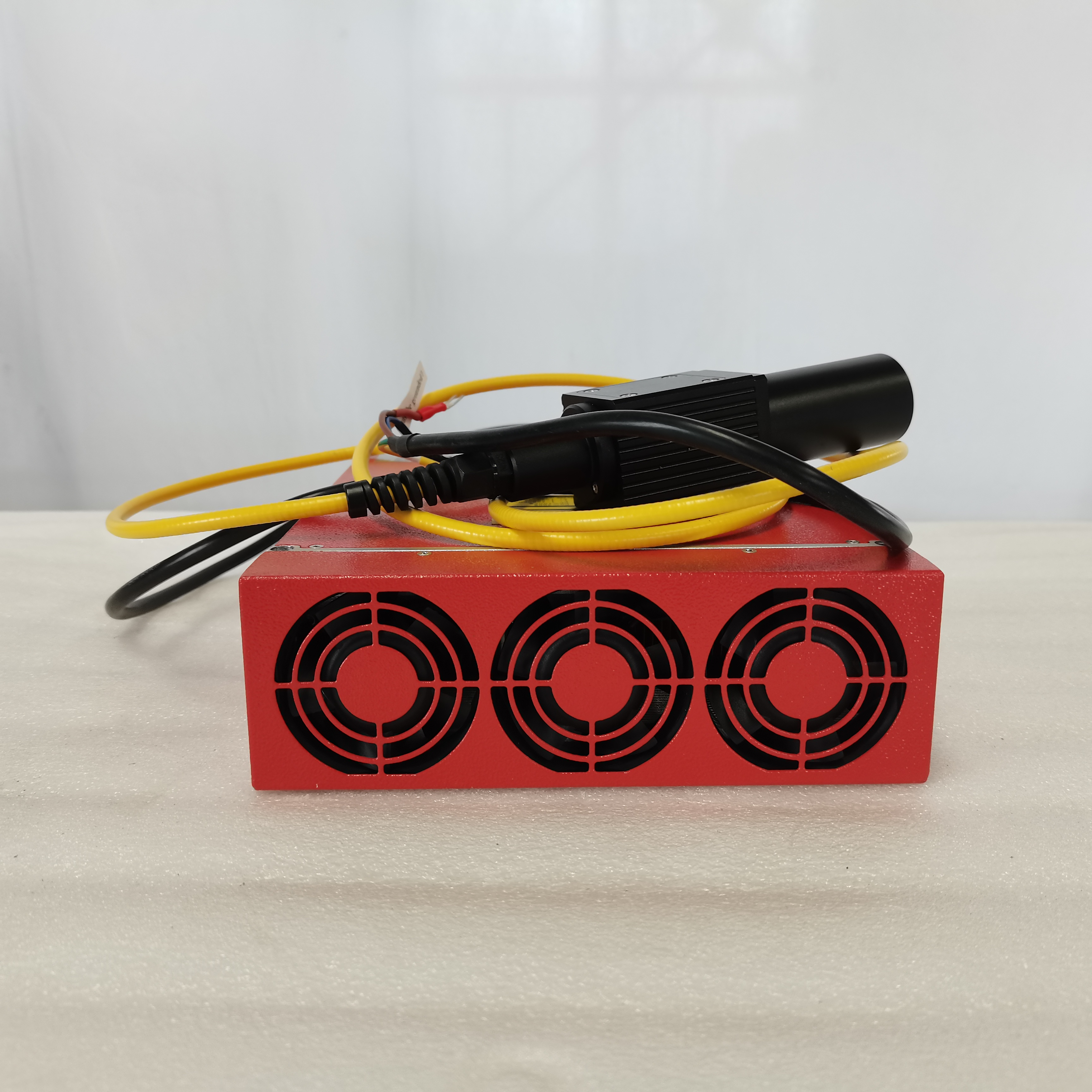

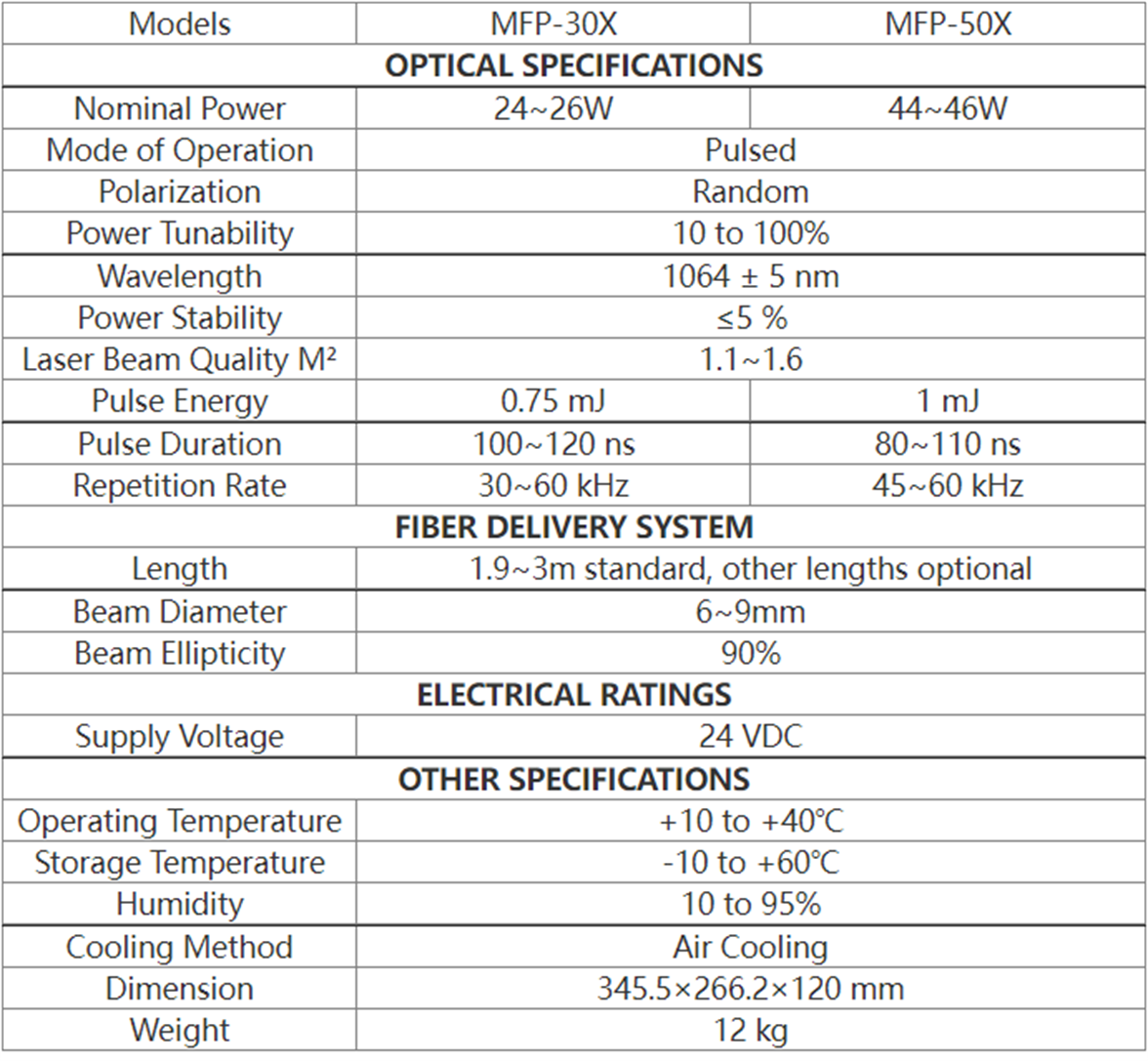

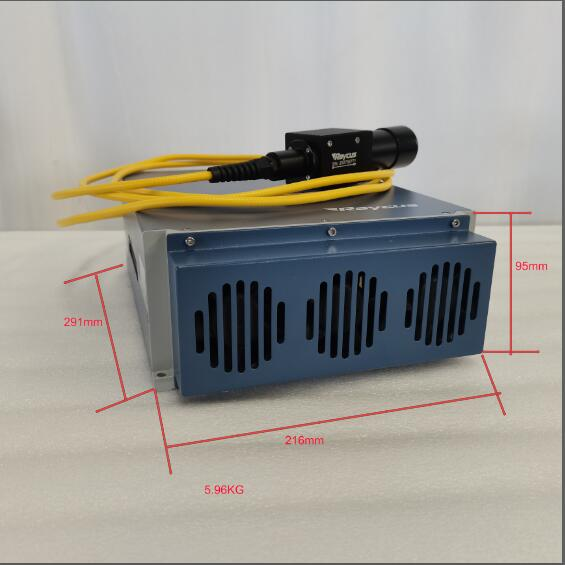

Sale price : $600/ set- $4500/ piece Q-switch series pulsed fiber laser is designed based on Q-switch oscillator and MOPA, offer a variety models from 30X to 50X. The laser is transmitted by fiber and isolator, and is controlled through a 25-pin interface. The Q-switched pulse fiber laser is suitable for intergration, and could meet the requirements of plastic marking, metal marking, engraving, etc.