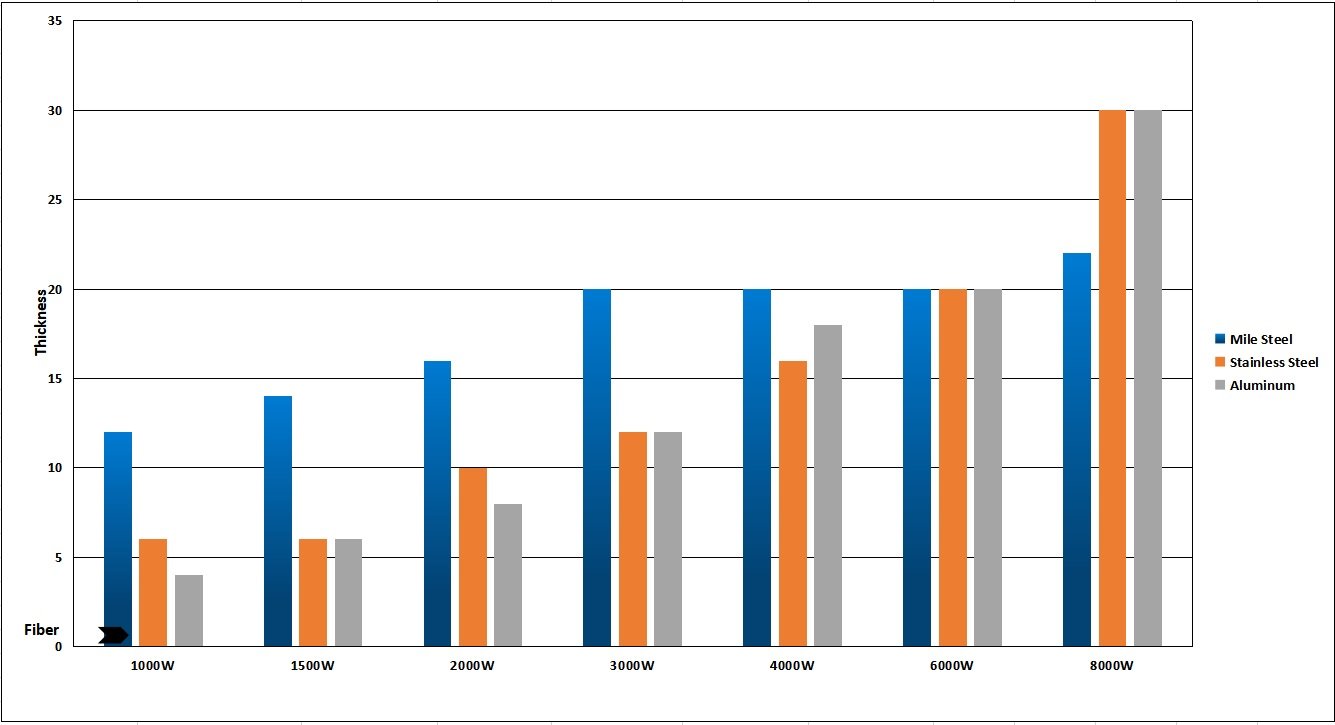

| Application | Laser Cutting | Applicable Material | Metal |

| Condition | New | Laser Type | Fiber Laser |

| Control Software | Cypcut | Laser Head Brand | Raytools |

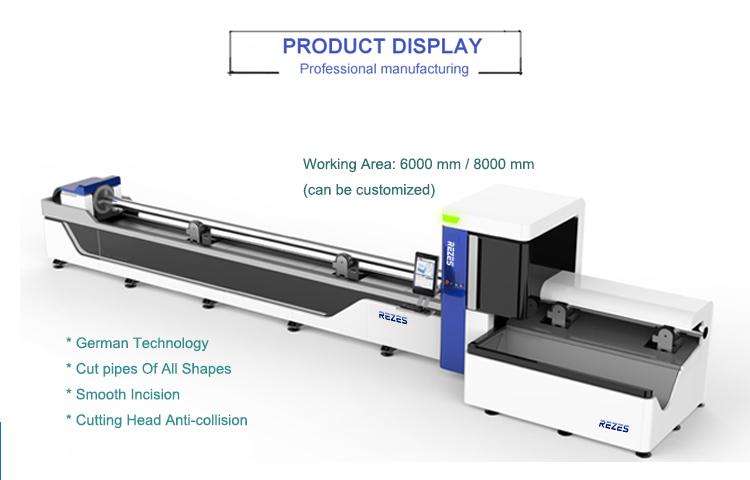

| Penumatic chuck | 20-350mm | Cutting Length | 3m/6m |

| Servo Motor Brand | Yaskawa motor | Laser source | IPG Raycus MAX JPT |

| Graphic Format Supported | AI, PLT, DXF, BMP, Dst, Dwg, DXP | CNC or Not | Yes |

| Key Selling Points | High Safety Level | Warranty of core components | 12 months |

| Mode of Operation | automatic | Positioning Accuracy | ±0.05mm |

| re-positioning accuracy | ±0.03mm | Peak Acceleration | 1.8G |

| Applicable Industries | Hotels, Building Material Shops, Manufacturing Plant | Pneumatical parts | SMC |

| Mode of Operation | continuous wave | Feature | Double platform |

| Cutting Speed | depending on power and thickness | Control Software | Tubepro |

| Core Components | Laser Generator | Guiderail Brand | HIWIN |

| Electrical parts | schneider | Warranty time | 3 years |