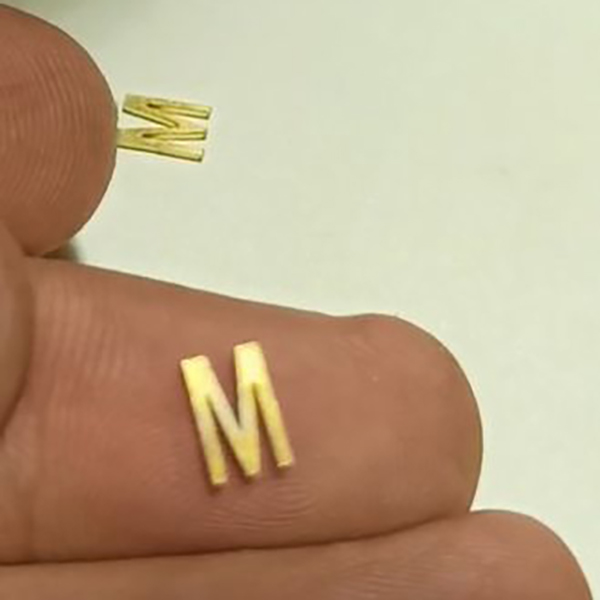

Widely used in electrical power, automobile manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising signs, car decoration, sheet metal production, lighting hardware, display equipment, precision components, metal products and other industries.High precision fiber laser cutting machine cutting gold and silver

Widely used in electrical power, automobile manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising signs, car decoration, sheet metal production, lighting hardware, display equipment, precision components, metal products and other industries.High precision fiber laser cutting machine cutting gold and silver| Product name | Gold Silver sheet Fiber Laser Cutting Machine |

| Laser wavelength | 1064nm |

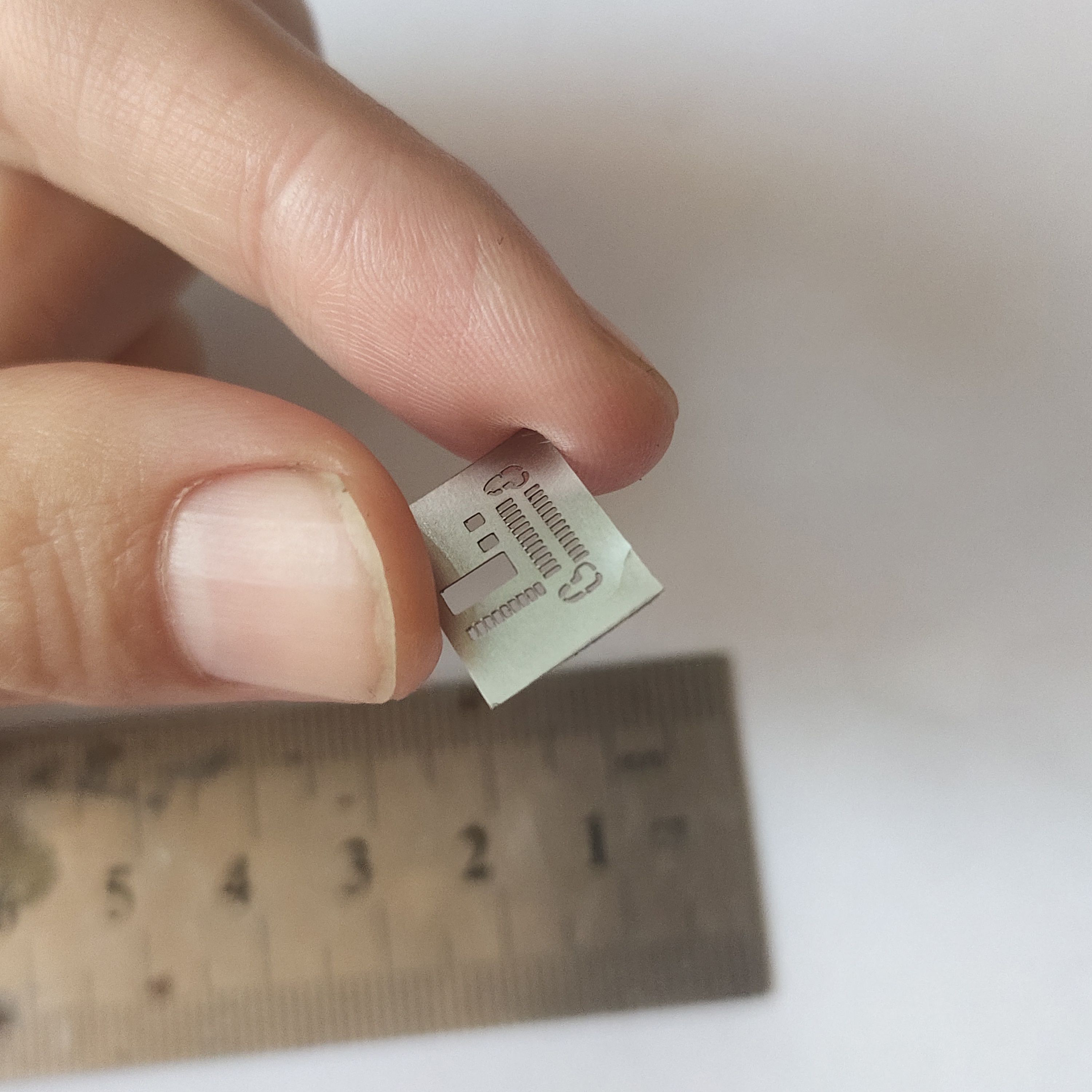

| Cutting size | 200mm*200mm(Cutomization available) |

| Location precision | ±0.005mm |

| Cutting gap width | 0.05-0.10mm |

| Laser source | Cooperated laser source |

| Laser source power | 1000w 1500w 2000w |

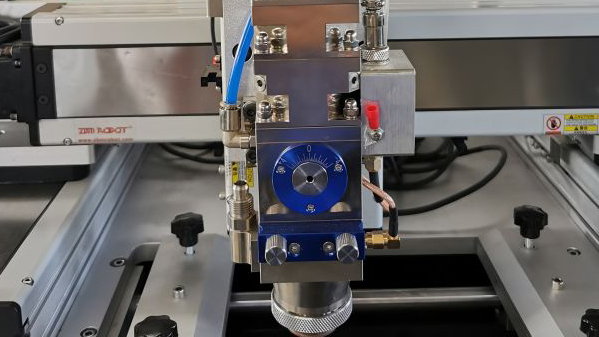

| Cutting head | Auto focus Ospri, Raytool available |

| Linear guide | Hiwin |

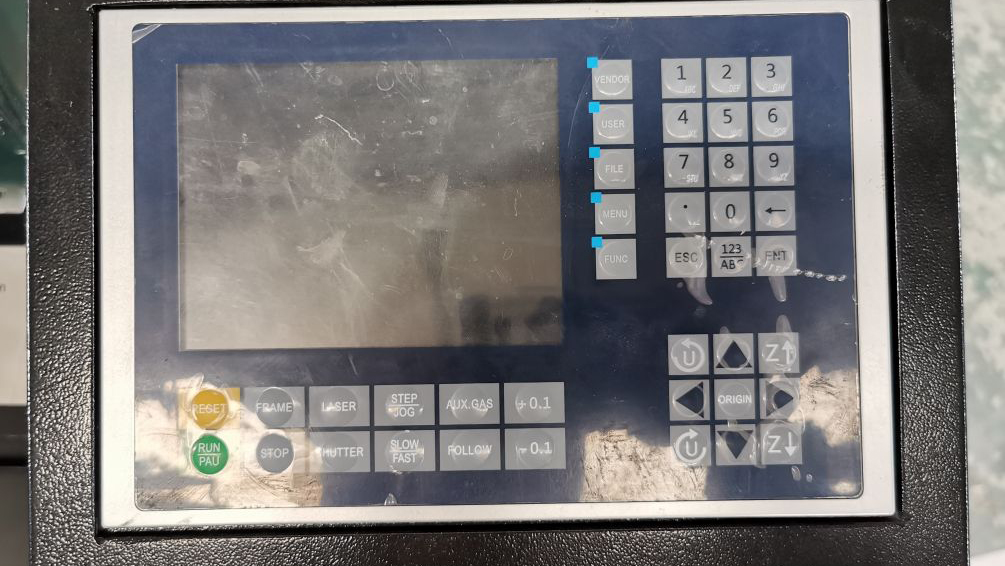

| Servo motor | Yaskawa motor |

| Max work speed | 20m/min |

| Max moving speed | 1G |

| Assisted gas | Compressed Air/ N2 |

| Work voltage | 220V 50HZ/60HZ |

| Machine weight | 220 kgs |

| Machine Size | 1000*750*1626mm |